Underground salt cavern hydrogen storage is a promising method to store hydrogen safely and efficiently. It involves utilizing naturally occurring or artificially created salt caverns to house compressed hydrogen.

This approach leverages the unique geological features of salt formations, capable of withstanding high pressures and providing secure containment. However, selecting an appropriate site for such storage requires detailed and complex evaluation, given the varied nature of geological formations.

The objective of the Patent

The patent by researchers from Sichuan University, introduces a coupling numerical simulation method specifically designed for site selection of underground salt cavern hydrogen storage. This method aims to bring precision and reliability to the process of identifying suitable geological sites for constructing hydrogen storage facilities.

Geological Data Collection

The method begins with the collection of geological data from the area where the salt cavern hydrogen storage is proposed. This data collection is crucial as it provides the necessary information about the rock formations, their properties, and existing conditions. Parameters such as rock composition, porosity, permeability, and existing stress fields are gathered to create an accurate representation of the site’s geological profile.

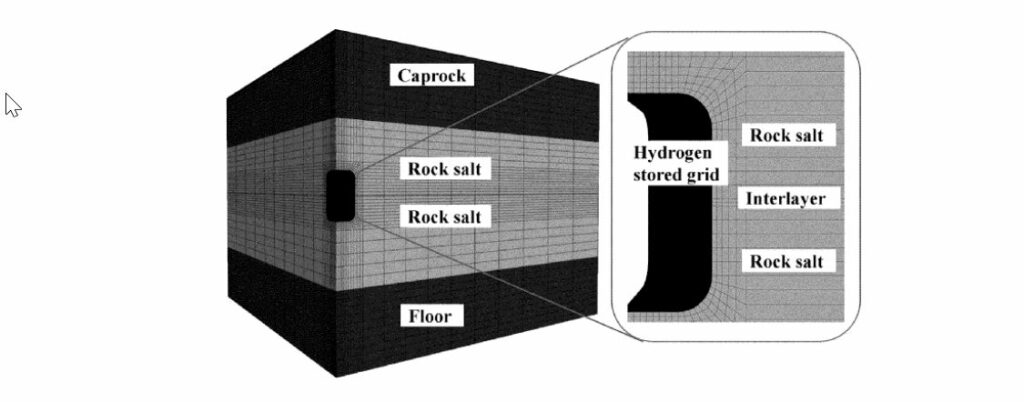

3D Modelling and Grid Meshing

Following data collection, a three-dimensional model of the area is established. This model serves as a digital twin of the proposed site, allowing for detailed analysis and simulation. Grid meshing is then performed on the 3D model. Grid meshing involves dividing the model into smaller, manageable segments or elements. This segmentation enables the precise calculation of various geological and engineering factors in subsequent steps.

Establishing and Balancing an Initial Coupling Field

An initial coupling field is established and balanced based on the geological model. This involves simulating the baseline conditions of the site before any excavation or storage activities commence. By balancing this initial field, researchers can ensure that the model accurately reflects the natural state of the geological formations, providing a reliable foundation for further simulations.

Excavation Simulation

With the balanced initial field, excavation simulation of the salt cavern hydrogen storage is carried out. This step models the process of creating the underground cavern, taking into account the stresses and structural changes that occur as rock is removed. The outcome of this simulation informs the feasibility and safety of cavern construction in the selected site.

Coupling Numerical Simulation Using TOUGH2MP and FLAC3D Software

Post-excavation, the geological model and related parameter values are imported into the TOUGH2MP and FLAC3D software. The synergy between these tools allows for a comprehensive simulation process:

– TOUGH2MP Software: Used to simulate hydraulic and thermal behaviors within the geological formations.

– FLAC3D Software: Employed for stress analysis and modeling the mechanical behaviors of the rock layers.

By coupling the stress model in FLAC3D with the hydraulic and thermal models in TOUGH2MP, a detailed simulation of the stress, hydraulic, and thermal coupling behavior process is achieved. This comprehensive approach ensures that all relevant factors are considered, accurately predicting how the site will perform under operational conditions.

The coupling numerical simulation method introduced by Sichuan University researchers represents a significant advancement in the field of underground salt cavern hydrogen storage. By integrating geological data collection, 3D modeling, balanced field establishment, excavation simulation, and coupling numerical simulation using advanced software, this method offers a robust framework for selecting suitable sites. This not only enhances the safety and efficiency of hydrogen storage but also contributes to the broader goal of developing sustainable energy solutions.