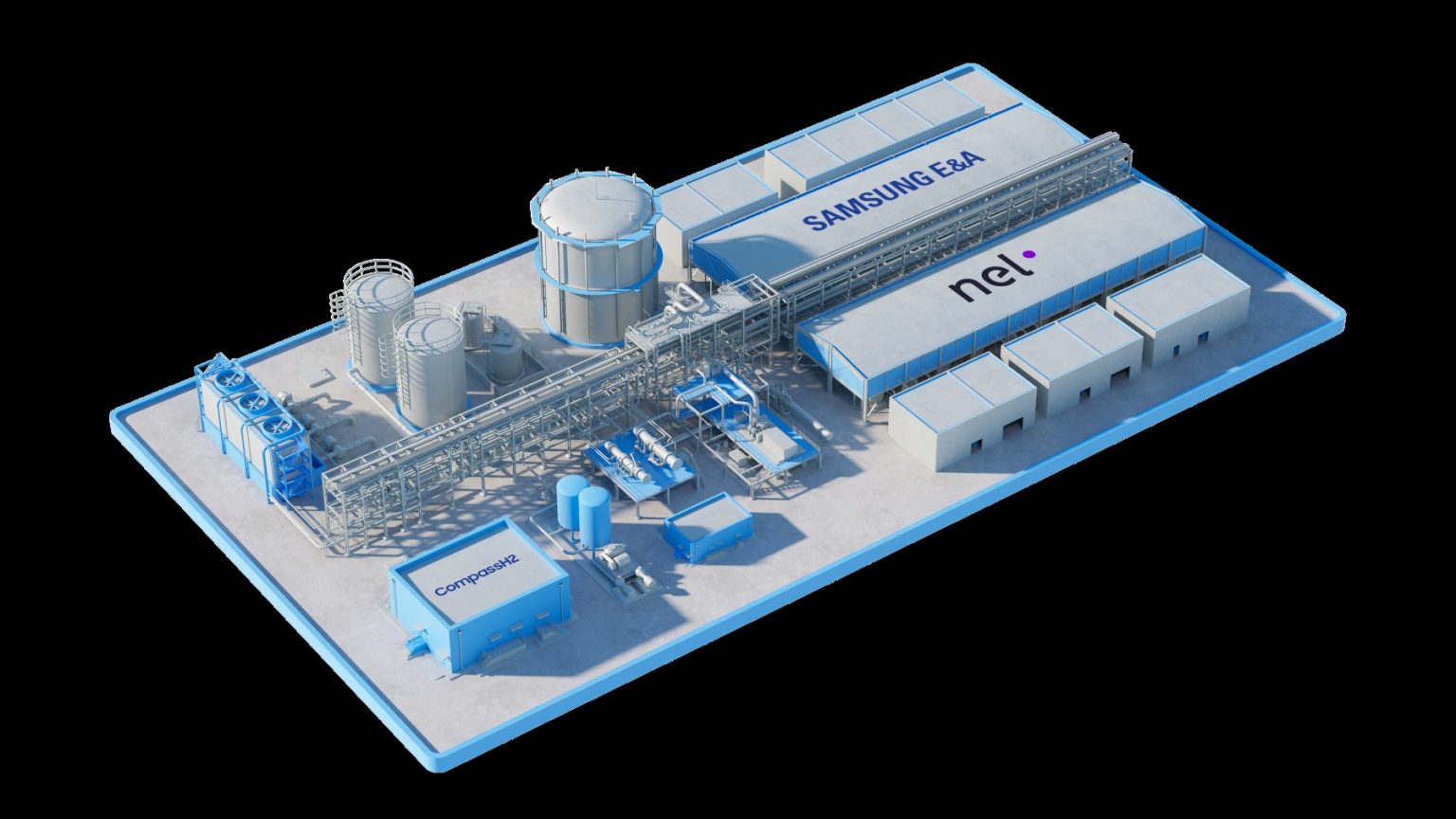

SAMSUNG E&A and Norway’s Nel have launched CompassH2, a green hydrogen production solution that promises to deliver some of the industry’s most competitive efficiency and cost metrics. Set to be unveiled officially at the World Hydrogen Summit 2025 in Rotterdam, the project signals a new phase in system-level optimization for large-scale hydrogen deployment.

With green hydrogen still facing persistent cost barriers—particularly in achieving the coveted sub-$2/kg threshold known to unlock competitiveness against grey hydrogen—CompassH2 is marketed as a turnkey solution designed to narrow the Levelized Cost of Hydrogen (LCOH) through integration and scale. At its core is the union of Nel’s high-efficiency electrolysers and SAMSUNG E&A’s engineering and lifecycle project execution, with the initial offering sized at 100 MW and modularly scalable.

CompassH2 integrates Nel’s proton exchange membrane (PEM) and alkaline water electrolysis (AWE) technologies, drawing on the company’s nearly century-long legacy in electrochemical systems. With electrolysis efficiency and hydrogen purity both critical to project economics and end-use compatibility, the new system reportedly sets a new standard, offering high purity hydrogen with minimized auxiliary loads and balance-of-plant energy demands.

SAMSUNG E&A, traditionally a heavy industrial player, is extending its role across the full project lifecycle—beyond engineering, procurement, and construction (EPC)—to encompass feasibility studies, electrolyser installation, and long-term operations and maintenance. By offering system-level performance guarantees, the companies aim to lower the bankability threshold for investors, easing financial close for utility-scale projects. This shift comes amid tightening financing conditions for capital-intensive clean hydrogen infrastructure.

Critically, CompassH2’s design approach supports downstream integration with green ammonia, methanol, and synthetic fuel production, providing value-chain flexibility. This is particularly relevant as demand grows for green molecules in sectors like shipping and aviation, which face limited electrification alternatives. According to SAMSUNG E&A, the compact system footprint and modular configuration make the solution particularly suited to complex project sites and phased buildouts.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.