The rise of sustainable and efficient energy solutions is crucial in today’s industrial landscape. The Saudi Arabian Oil Company’s patent, titled “Natural Gas Processing with Integrated Hydrogen Generation,” encapsulates an innovative step in this direction.

This patent covers operating a natural gas processing plant that integrates hydrogen production into its core processes, promising energy efficiency and sustainability enhancements.

Natural Gas Processing

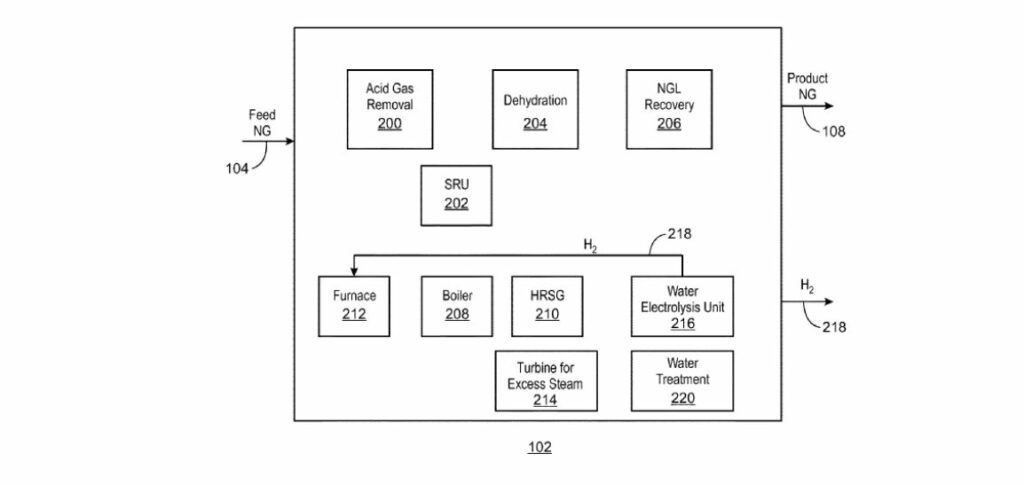

At the heart of this patented method is the processing of feed natural gas to produce product natural gas. The process involves several key steps to refine the feed natural gas. Initially, the gas undergoes purification stages to remove unwanted components such as acid gas, water, and non-methane hydrocarbons. This purification ensures that the resultant product, natural gas, meets the required standards for commercial and industrial applications.

Energy Generation in the Processing Plant

A notable aspect of this patent is its approach to energy generation within the natural gas processing plant. Fuel is supplied to a furnace that undergoes combustion to heat a boiler and a Heat Recovery Steam Generator (HRSG). This heating process generates high-pressure (HP) steam, which is then used to drive a turbine. The turbine’s operation yields electricity, while the HP steam is converted to low-pressure (LP) steam.

Hydrogen Generation from Excess Steam

One innovative feature of this patented technology is excess low-pressure steam in the plant. Instead of letting this LP steam waste, it is subjected to electrolysis. The electrolysis process splits water molecules in the steam to generate hydrogen gas. This hydrogen gas is then combined with the fuel for combustion in the furnace, thus creating a self-sustaining loop that enhances the overall energetic efficiency of the plant.

Sustainability and Efficiency

The integration of hydrogen generation within the natural gas processing plant offers several benefits. The plant reduces its dependency on external hydrogen supplies by generating hydrogen on-site and using it to supplement furnace fuel. Additionally, this method takes advantage of surplus steam, which might otherwise go unused, making the entire process more efficient and environmentally friendly.

The Saudi Arabian Oil Company’s patent for “Natural Gas Processing with Integrated Hydrogen Generation” represents a significant advance in natural gas processing technology. Incorporating hydrogen generation directly within the plant’s operation achieves higher energy efficiency and sustainability. This innovation reflects a growing trend towards more integrated and self-sufficient industrial processes, highlighting the potential for technological advancements to contribute to a more sustainable energy future.