A collaborative research team in South Korea has developed a revolutionary catalyst that could significantly reduce the cost of producing green hydrogen, paving the way for a cleaner future.

The research, led by Professor Gwang-yeol Lee of Korea University, involved teams from Dongguk University, Sungkyunkwan University, and the Korea Institute of Science and Technology (KIST). Their focus was on improving the efficiency and affordability of anion exchange membrane water electrolysis (AEMWE), a key technology for producing green hydrogen.

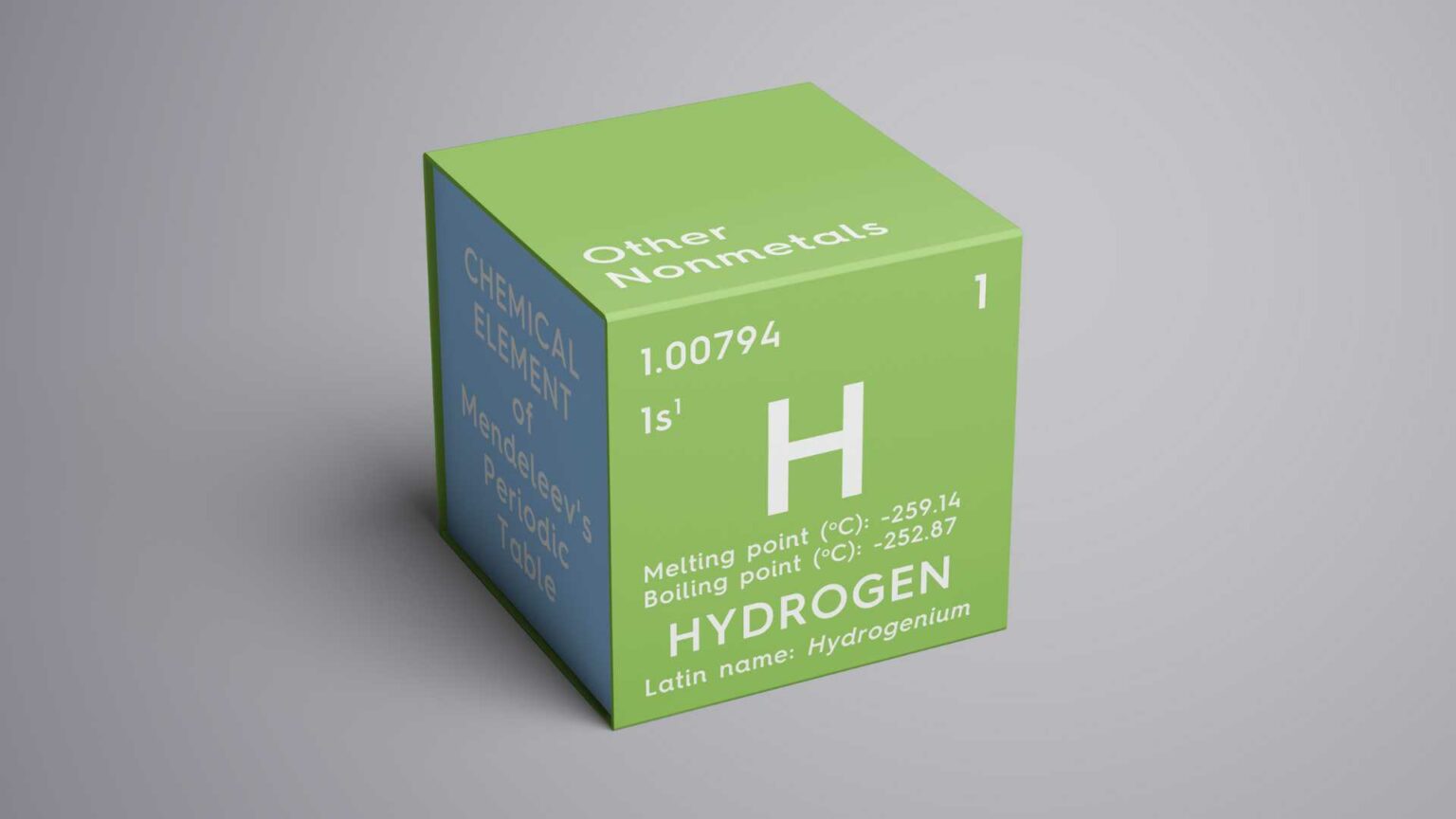

Green hydrogen, produced through electrolysis using renewable energy sources, is a promising clean energy alternative. However, its widespread adoption has been hindered by the high cost associated with the current state of AEMWE technology. This stems from the limitations of the existing catalyst materials, which suffer from low activity and durability.

The Korean research team addressed these challenges by developing a novel ternary material consisting of platinum, ruthenium, and phosphorus, structured as a double-walled nanotube. This innovative design, combined with a new anion-cation exchange method for controlling nanoparticles, resulted in a highly efficient and durable AEMWE catalyst.

The researchers observed a significant improvement in the current density of their AEMWE catalyst compared to commercially available options. Their new catalyst achieved a current density of 9.40 A/cm2, exceeding the 5.44 A/cm2 of standard platinum catalysts by a factor of 1.7. Additionally, the research team demonstrated the long-term durability of their catalyst, with a stable performance exceeding 270 hours.