As the demand for cleaner and more efficient automotive technologies grows, Hyundai Motor Company has filed a patent for an innovative system designed to lubricate hydrogen injectors in vehicles.

This technology aims to enhance the efficiency and longevity of hydrogen combustion engines, potentially setting a new standard in sustainable automotive solutions.

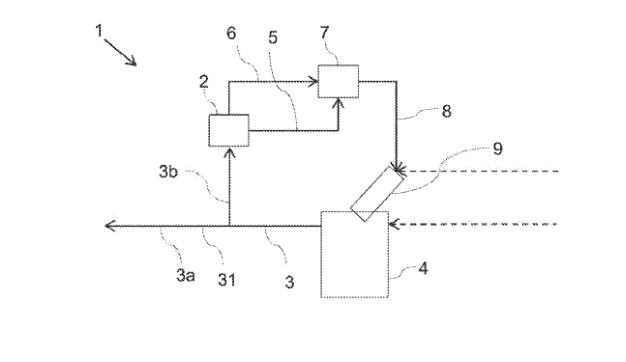

At the core of this system is a sophisticated extraction and separation device. This component is engineered to collect a specific fraction of exhaust gas from a hydrogen combustion engine. The collected exhaust gas then undergoes a separation process to divide it into two primary components: liquid water and dried exhaust gas. This separation is essential as it prepares the exhaust gases for further processing within the system.

Generation of Nitric Acid

Following the separation process, the dried exhaust gas and the extracted liquid water are directed to a reactor. This reactor plays a pivotal role in the system by generating nitric acid. It achieves this by utilizing the nitrogen oxide content present in the dried exhaust gas along with the liquid water. Nitric acid, known for its lubricating properties, is crucial for maintaining the functionality and efficiency of hydrogen injectors.

Lubrication of Hydrogen Injector

The generated nitric acid is subsequently delivered to the hydrogen injector. This innovative approach to lubrication not only ensures that the hydrogen injector operates smoothly but also potentially reduces wear and tear, resulting in enhanced longevity and performance. The use of a naturally occurring byproduct like nitric acid emphasizes the system’s alignment with eco-friendly practices.

Hyundai’s patent illustrates a promising step forward in the evolution of hydrogen fuel technology. By utilizing exhaust gas byproducts for essential engine maintenance tasks, this system highlights a sustainable approach to vehicle design.