A recent patent filed by Primetals Technologies Germany GmbH introduced a sophisticated system to enhance the efficiency of hydrogen and electric energy integration in steel production.

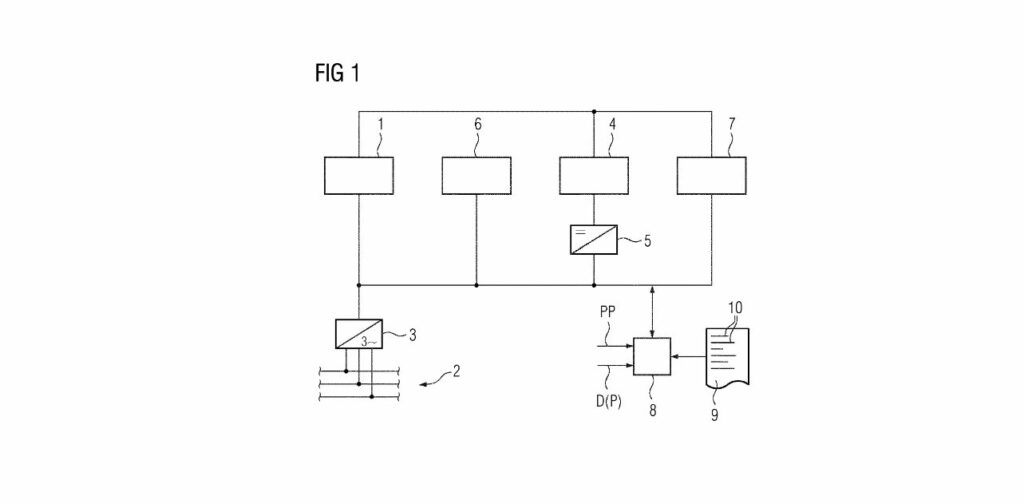

The inventors behind this innovation have devised a comprehensive system that combines various sub-systems—namely, a steel industry system, an electrolysis system, an electric energy storage device, and a hydrogen storage device. These sub-systems are intricately connected to facilitate the efficient transfer of electric energy and hydrogen.

Features and Technological Advancements

The centerpiece of this innovation lies in its intelligent controller. This controller monitors the current states of all sub-systems and considers multiple factors, such as the desired production plan, the expected price of electric energy from the supply grid, and the design limits of each sub-system. By varying the operating modes based on these parameters, the controller aims to minimize costs associated with electric energy consumption while enhancing the productivity of the steel industry system. This approach represents a significant improvement over existing technologies by dynamically adjusting the operations to optimize overall efficiency.

Potential Applications

The primary application of this patented technology is in the steel production industry. By integrating electric energy and hydrogen management into a unified system, steel producers can significantly reduce energy costs and improve production efficiency. Beyond steelmaking, this system could potentially be adapted for other heavy industries where efficient energy and hydrogen use are critical.

Impact on the Hydrogen Market

This patent could advance the hydrogen market by demonstrating practical, efficient methods for integrating hydrogen into large-scale industrial processes. As industries seek to reduce carbon footprints and transition to cleaner energy sources, adopting such technologies could spur increased demand for hydrogen, driving growth and innovation within the market.

Technical Specifications and Methodologies

The patent details several key technical aspects:

1. The system comprises a steel industry system, an electrolysis system, an electric energy storage device, and a hydrogen storage device.

2. These sub-systems are interconnected to facilitate the transfer of electric energy and hydrogen.

3. An advanced controller monitors the current states of the sub-systems and varies their operating modes to minimize a defined cost function.

4. The cost function considers electric energy consumption, the operating modes of the sub-systems, expected final states, and the productivity of the steel industry system.

By leveraging these technical innovations, the system aims to balance operational costs and production efficiency.

Key Takeaways

This patent by Primetals Technologies Germany GmbH introduces a cutting-edge system that integrates hydrogen and electric energy management within the steel production process. Using an intelligent controller to adjust operations dynamically offers significant improvements in efficiency and cost-effectiveness. The potential impact on the hydrogen market and its applicability in heavy industries underscores the system’s importance without overstating its immediate significance. Comparatively, it outpaces existing solutions by offering a more responsive and integrated approach to energy and hydrogen management in industrial applications.