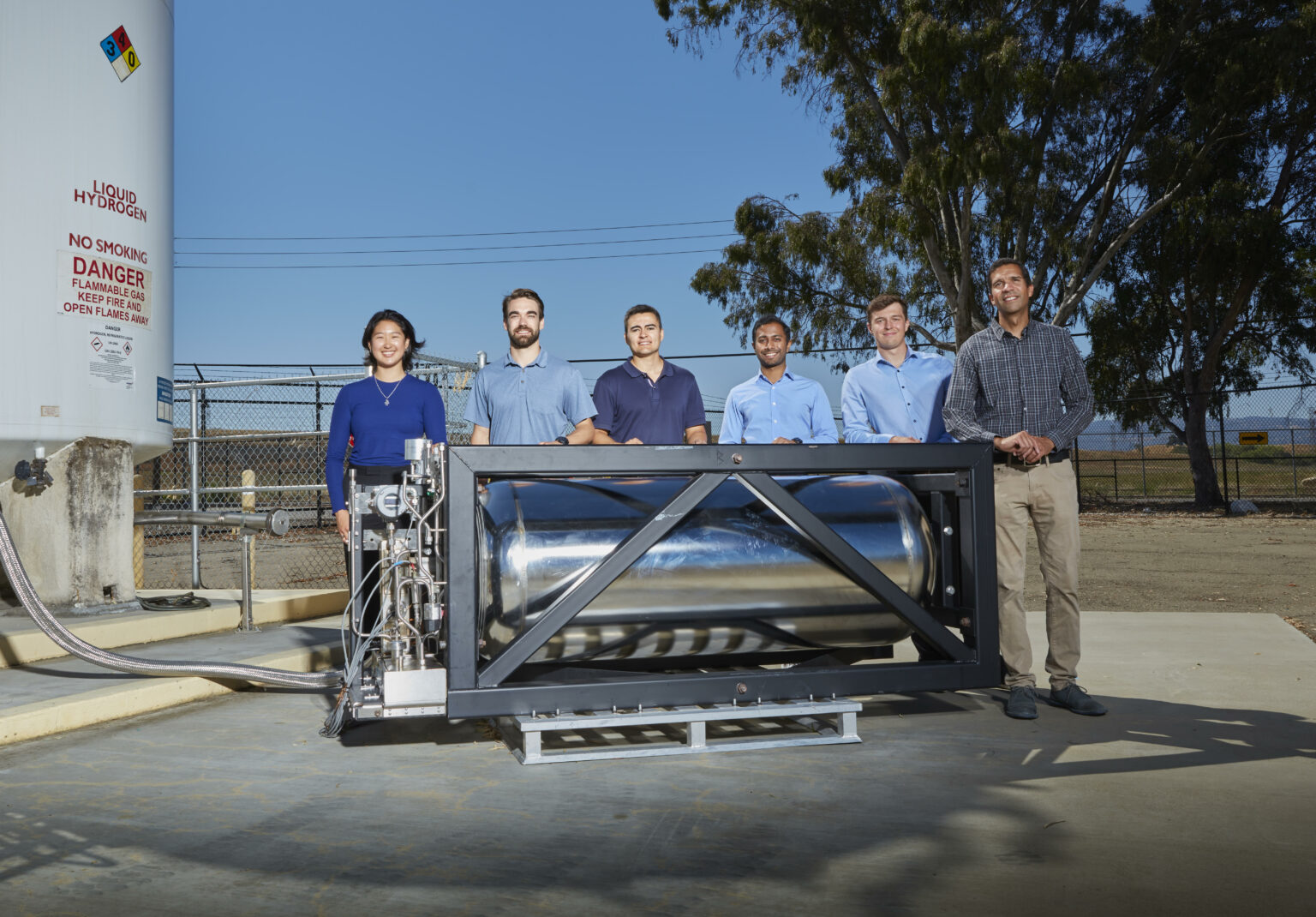

Verne and Lawrence Livermore National Laboratory (LLNL) demonstrated a single cryo-compressed hydrogen (CcH2) system with a capacity of 29 kilograms, close to three times greater capacity than previously known examples.

This system is the first CcH2 system large enough for use in heavy-duty transportation systems. For example, two such systems can be frame- mounted to a Class 8 truck, and enable a range of over 500 miles, according to Verne analysis.

Heavy-duty vehicles including trucks, ships and planes are responsible for 23 percent of U.S. GHG emissions, yet are difficult to decarbonize due to their high energy requirements. Current battery electric and hydrogen storage methods (liquid and compressed gas) do not provide sufficient energy density to power Class 8 trucks. CcH2 achieves 27 percent greater hydrogen storage density than liquid hydrogen and more than 75 percent greater hydrogen storage density than compressed gaseous hydrogen. The energy stored in Verne’s 29 kilogram CcH2 tank is roughly equivalent to a one- megawatt-hour battery storage system, while weighing only about 400 kg versus the one-megawatt-hour battery which weighs around 5,000 kg. This magnitude improvement in gravimetric energy density is a major reason why hydrogen is the preferred fuel for the heavy-duty industry.

Verne and LLNL have worked together for the past two years to test Verne’s hydrogen- storage systems, building on early CcH2 research at LLNL that was started over 25 years ago by Dr. Salvador Aceves. In this test, Verne implemented a test manifold that enables the testing of multiple components at once. This allows Verne to test and validate various types of safety valves, operating valves, and sensors.

“Despite the promise from early hydrogen-fueled truck pilots, the efficient storage of hydrogen onboard trucks, ships and planes remains one of the main challenges to unlock a zero-emission future. Verne has developed high-density, lightweight hydrogen storage systems for use onboard heavy-duty vehicles at low cost. Our solution builds upon decades of research pioneered at Livermore to provide a reliable, scalable and cost-effective storage solution. We could not have done this without the team at Livermore. It’s exciting to see this project head toward the commercialization phase where it can be adopted across the heavy-duty sector” said David Jaramillo, co-founder of Verne.

Verne’s CcH2 system is compact enough that it can fit where diesel tanks are typically installed on a Class 8 truck, on the side of the truck between the wheels. Verne has received interest in their CcH2 systems from a variety of industry stakeholders, including Amazon, an investor in Verne.