VSPARTICLE’s nanoporous catalyst layer technology has passed peer-reviewed validation, confirming performance benchmarks that could mitigate one of the most pressing bottlenecks in proton exchange membrane (PEM) electrolyzer scaling—the scarcity of iridium.

The company’s collaboration with Plug Power and the Center for Clean Hydrogen at the University of Delaware achieved operational performance using up to 90% less iridium than conventional designs, a finding that may reshape the economics of green hydrogen production.

The results, presented at the Electrochemical Society (ECS) Meeting in Chicago, exceeded the U.S. Department of Energy’s 2026 targets for both iridium utilization and stack performance. The implications are significant: according to the International Energy Agency, hydrogen produced from steam methane reforming (SMR) still costs between $1.50 and $2.50 per kilogram, whereas VSPARTICLE’s data supports the technical feasibility of renewable hydrogen at around $1/kg — a cost parity threshold long regarded as the sector’s economic tipping point.

PEM electrolysis has long been favored for its ability to handle the volatility of renewable energy inputs. Yet its dependence on iridium — one of the rarest platinum group metals, with global output of only 7–8 tones annually — has restricted production scale. Typical fabrication techniques demand iridium loadings of 1–2 mg/cm², with much of the material poorly utilized due to inefficient coating and bonding processes.

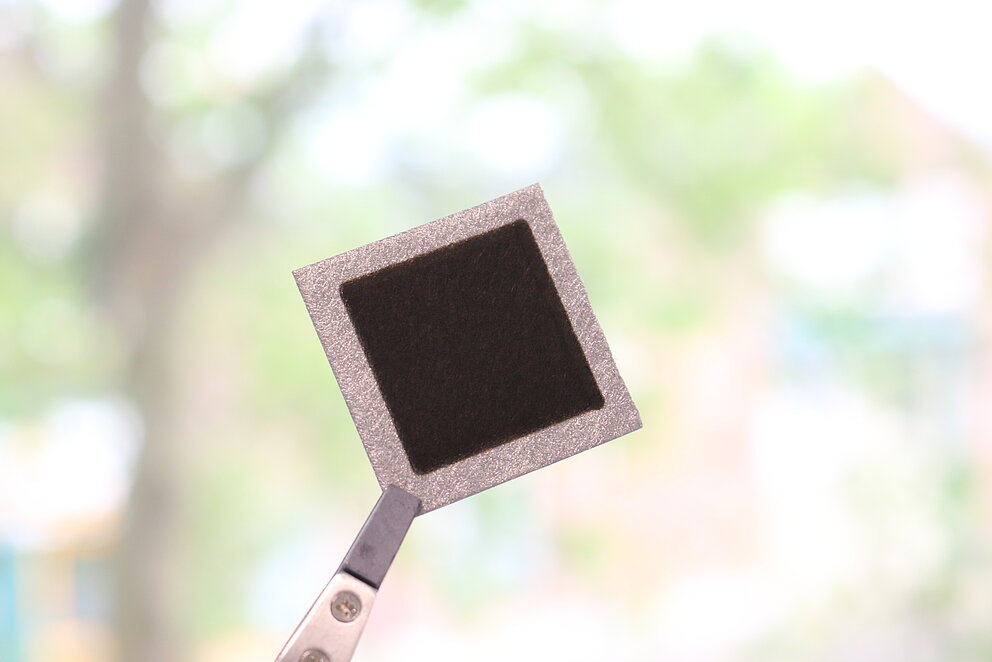

VSPARTICLE’s spark ablation-based approach creates a nanoporous, solvent-free catalyst layer that maximizes electrochemical surface area without relying on PFAS-based ionomers. This structural uniformity improves the utilization rate of iridium atoms while reducing processing complexity and waste. The approach also enhances recyclability — an increasingly critical factor given the European Union’s tightening material recovery mandates for electrolyzer components.

Plug Power’s R&D validation underscores the commercial potential of the technology. “The performance at 0.4 mg/cm² is exceptional,” said Dr. Thomas Valdez, Senior R&D Manager at Plug Power. “In our evaluation, VSPARTICLE’s electrodes demonstrate the durability and current density required for large-scale systems. This level of iridium utilization is essential for Plug to achieve its cost-reduction and deployment goals.”

The validation comes at a pivotal moment for the hydrogen sector. Renewable electricity prices — particularly for solar PV — have declined by roughly 90% over the past decade, according to IRENA, narrowing the cost gap between green and fossil-based hydrogen. Yet, as materials costs remain stubbornly high, innovations in catalyst design are viewed as the final lever for reaching the DOE’s “Hydrogen Shot” target of $1/kg clean hydrogen.

Dr. Yushan Yan, director of the Center for Clean Hydrogen, described the findings as a step toward industrial de-risking. “This work directly addresses the most significant materials challenge in PEM electrolysis,” he said. “The combination of ultra-low iridium loading and proven durability could prevent an iridium supply crisis and redefine the economics of green hydrogen. The same deposition principles may also benefit anion exchange membrane systems.”

VSPARTICLE is expanding its in-house coating capacity to support pilot and early commercial projects with major PEM electrolyzer manufacturers. Multiple partners have scheduled integration trials and commercial-scale testing beginning in 2026, suggesting that industrial adoption could follow rapidly if long-term durability data continues to align with lab results.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.