Researchers Nicolás Martínez-Ramón, María Romay, Diego Iribarren, and Javier Dufour have conducted a comprehensive life-cycle assessment (LCA) of hydrogen produced through chemical looping dry reforming of biogas. The study, published in the International Journal of Hydrogen Energy, explores the environmental and economic impacts of this innovative hydrogen production pathway.

Context and Relevance

Hydrogen is widely regarded as a key component in the transition to a low-carbon economy, crucial for reducing greenhouse gas emissions across various industries. Traditional hydrogen production methods, such as steam methane reforming, pose significant environmental challenges, prompting the search for greener alternatives. This research is particularly relevant as it investigates a method leveraging biogas—a renewable resource—to produce hydrogen, potentially offering a more sustainable solution.

Main Findings

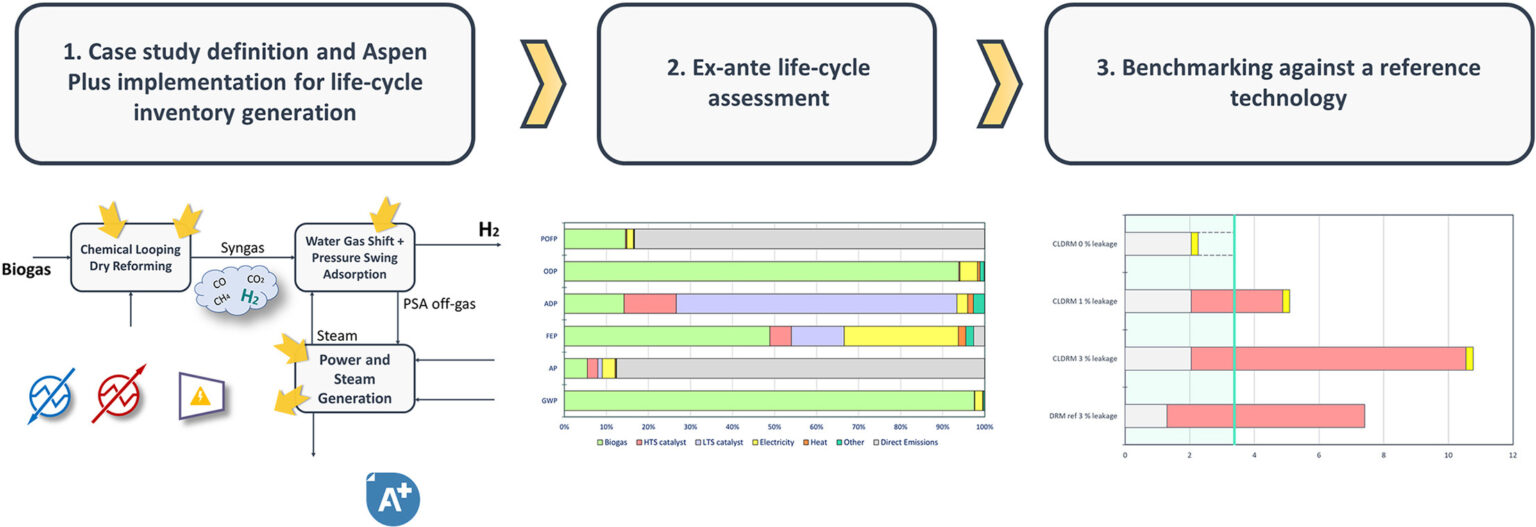

The study provides an in-depth analysis of the life-cycle impacts of producing hydrogen via chemical looping dry reforming of biogas. Key findings include:

1. Environmental Impacts: Hydrogen production through this method significantly reduces greenhouse gas emissions compared to conventional fossil-fuel-based processes.

2. Energy Efficiency: The process demonstrates a high energy efficiency, making it a viable option for sustainable hydrogen production.

3. Economic Viability: When considering the full life-cycle costs, this method of hydrogen production could be economically competitive, especially as carbon pricing and renewable energy adoption increase.

Potential Applications

The integration of this hydrogen production method can have wide-ranging applications, including:

– Industrial Use: Hydrogen is a critical feedstock in chemical industries, and a cleaner production method could mitigate industry-wide emissions.

– Energy Storage: Hydrogen generated through this method can serve as an energy carrier, aiding in grid stabilization and renewable energy storage.

– Transportation: Hydrogen fuel cells for vehicles represent a growing market, and sustainable hydrogen production is essential for this sector’s expansion.

Market Relevance

As the hydrogen market grows, demand for greener production methods will surge. This research highlights an approach that meets this demand and aligns with global sustainability goals. Key benefits for the market include reduced carbon footprint, enhanced energy security through local biogas sources, and potential cost reductions over time.

Technical Details and Methodologies

The research employs a rigorous LCA framework, analyzing various stages from biogas production to hydrogen output. Key methodologies include:

– Chemical Looping: Utilizes a metal oxide for conversion, improving efficiency and reducing emissions.

– Dry Reforming: Involves the conversion of biogas (methane and CO2) into hydrogen, a process that reduces reliance on water—a crucial aspect in regions with water scarcity.

Broader Implications

This study underscores the potential for chemical looping dry reforming of biogas to revolutionize hydrogen production. With growing emphasis on circular economies and sustainable practices, such methods could help reduce waste, enhance resource efficiency, and contribute to the broader adoption of renewable technologies.

Key Takeaways

– Environmental Benefits: Significant reduction in greenhouse gas emissions.

– Economic Feasibility: Potential for favorable life-cycle cost analysis.

– High Efficiency: Promising energy efficiency compared to traditional methods.

– Market Impact: Aligns with global trends towards sustainable hydrogen production.