A recent patent, “Electrical Distribution Plate for an Electrolyser Stack,” filed by John Cockerill Hydrogen Belgium, introduces innovation tailored to enhance the performance of electrolyzer stacks. This electrical distribution plate features a novel design that targets improved functionality within hydrogen production systems.

Features

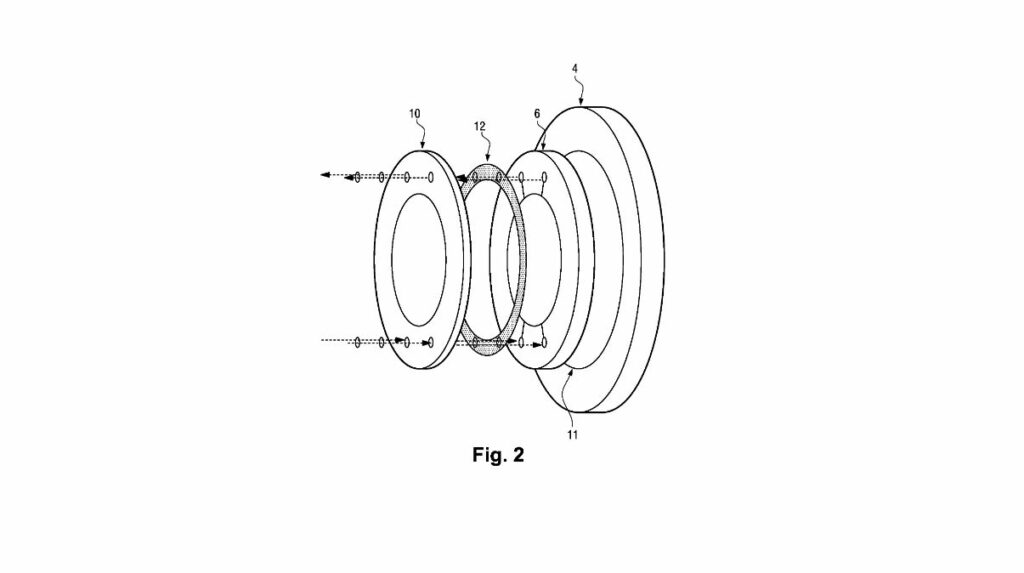

The electrical distribution plate described in the patent boasts two primary faces. The first face is designed to interface with a block of electrolytic cells, while the second face faces the bottom plate of the electrolyzer stack. A distinctive feature of this plate is the inclusion of at least one recess and multiple orifices. These orifices traverse the plate, opening at one end on the first face and at the other end on the second face, either at the recess or outside it.

The grooves connecting these orifices to the recesses add an added layer of innovation. This meticulous routing ensures efficient distribution and flow management, minimizing resistance and potential blockages within the stack. Unlike conventional designs, this new architecture facilitates more uniform electrical distribution and electrolyte flow, enhancing the overall efficiency of the electrolyzer stack.

Applications

This technology’s primary application lies in hydrogen production systems, specifically in electrolyzer stacks used for water electrolysis. By improving the efficiency and reliability of these stacks, the technology can be pivotal in large-scale hydrogen generation setups, which are critical for green hydrogen initiatives aiming to reduce carbon emissions. This improved distribution plate can be employed in industrial hydrogen production, renewable energy storage, and even smaller-scale operations where efficiency gains can translate to cost savings.

Market Impact

The introduction of this advanced electrical distribution plate is poised to significantly impact the hydrogen market. As industries worldwide increasingly lean towards sustainable energy solutions, the demand for efficient hydrogen production systems is rising. This patent could lead to more robust and cost-effective electrolyzer stacks, accelerating the adoption of hydrogen as a clean energy source. Reduced operational costs and increased efficiency can make hydrogen more competitive than other renewable energy technologies.

Technical Specifications and Methodologies

Key technical specifications of the distribution plate include:

– Two main faces: one for interfacing with electrolytic cells and the other with the bottom plate.

– At least one recess formed on the second main face.

– Multiple orifices that pass through the plate, connecting the first and second faces.

– Grooves that open into these orifices and recesses.

The methodology involves precise engineering to ensure that the grooves and orifices are optimally placed to provide consistent and efficient electrical current and electrolyte flow distribution.

Key Takeaways

The “Electrical Distribution Plate for an Electrolyser Stack” patent showcases a strategic advancement in electrolyzer design, emphasizing improved efficiency and reliability. With its innovative flow and electrical management features, this technology offers significant potential for advancing hydrogen production. As the market leans more towards sustainable energy solutions, this patent could play a crucial role in hydrogen’s broader adoption and competitiveness as a clean fuel source.