In recent developments within the field of hydrogen combustion engines, significant attention has been drawn to improving the efficiency and control of fuel delivery systems. The newly patented gas injector by Schaeffler Technologies represents a noteworthy leap in this area.

Designed specifically for hydrogen combustion engines, this innovation focuses on optimizing the pressure control and injection process to enhance engine performance.

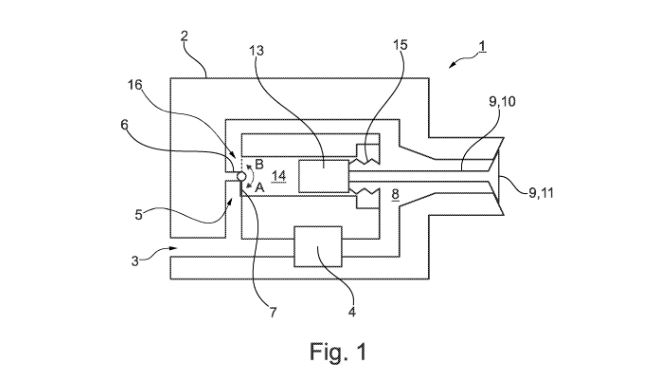

The patent for the gas injector encompasses several key components. First, it features a high-pressure port that serves as the initial entry point for the gas. This port connects to a pressure reducer, a crucial element responsible for regulating the high pressure of hydrogen gas to a more manageable level before it progresses through the system. Downstream from the pressure reducer, an injection opening is situated, which can be effectively sealed using a specialized valve. This arrangement ensures precise delivery and control of hydrogen gas into the combustion engine.

One of the most notable aspects of the patent is the method of valve adjustment. Emphasizing precision, a uniquely designed piston, loaded on both sides, governs the valve’s operation. On one side, the piston is influenced by the pressure downstream of the pressure reducer. The other side of the piston can be selectively exposed to either the same downstream pressure or to the higher pressure present at the high-pressure port. This is achieved via a switching valve assembly, which grants the injector its ability to finely tune the pressure exerted on the valve.

The innovative design of this gas injector promises several advantages for hydrogen combustion engines. By allowing dynamic adjustment and precise control of hydrogen delivery, the injector can potentially enhance combustion efficiency, reduce emissions, and improve overall engine performance. This technological advancement aligns with the growing interest in hydrogen as a clean energy source for automotive applications.