A recently published patent by Air Products and Chemicals, Inc., filed on August 1, 2024, introduces a groundbreaking method focused on reducing the water content of ammonia utilized in ammonia cracking processes.

This innovation, designed by a team of inventors at the company, addresses significant issues surrounding the use of water intolerant cracking catalysts and enhances the efficiency of hydrogen production.

Features and Improvements

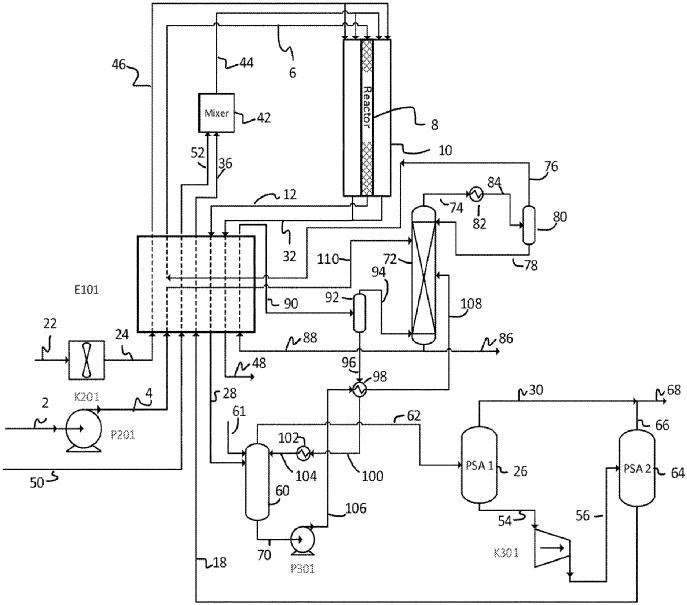

This patent outlines a method to decrease the water content present in ammonia before it undergoes the cracking process. One of the crucial aspects of this innovation is the enhancement of cracking catalyst performance. Traditionally, water content in ammonia can interfere with these catalysts, leading to suboptimal hydrogen yields and compromised catalyst longevity. By significantly reducing the water content, the patented process ensures the seamless function of water intolerant catalysts, resulting in more efficient hydrogen production.

Additionally, the process boasts a mechanism for recovering and recycling ammonia from the cracked gas. This means that not only is the initial efficiency improved, but the system also promotes sustainability by curtailing resource wastage.

Potential Applications

The primary application for this patented technology is in hydrogen production facilities where ammonia is used as a feedstock. The improved efficiency and catalyst longevity mean that plants can operate more continuously and economically, producing hydrogen necessary for various industrial purposes, including fuel cells, ammonia synthesis, and refining processes.

The process described in the patent involves a specific sequence of treating ammonia to reduce its water content before introducing it to the cracking catalyst. Though the patent does not detail the exact chemical process or mechanical setup in this summary, it emphasizes the importance of maintaining low water levels to ensure optimal catalyst performance.