The recent patent filed by Taiyo Nippon Sanso Corporation outlines a hydrogen gas production system designed to improve efficiency and effectiveness in producing hydrogen gas with a high recovery rate and an optimal deuterium D content ratio.

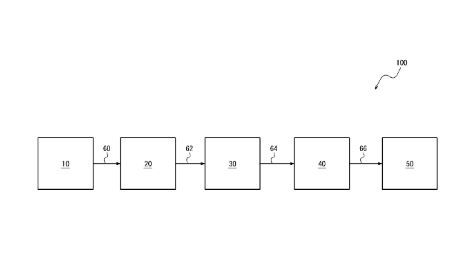

This innovation stands as an important step in optimizing hydrogen production, which is crucial for various industrial and energy applications. The hydrogen gas production system consists of several interrelated components, each playing a vital role in ensuring the efficient production and storage of hydrogen gas. The first tank accommodates the raw material water, which includes heavy water. An electrolysis device is employed to electrolyze this raw material water, resulting in the production of hydrogen gas. Subsequently, a reservoir stores this hydrogen gas for further use.

One of the standout features of this patented system is its advanced control mechanisms that ensure continuous and high-efficiency production of hydrogen gas. The system is equipped with a liquid feed device and a gas feed device. The liquid feed device is designed to replenish raw material water from the first tank to the electrolysis device as needed. Meanwhile, the gas feed device ensures the continuous feeding of generated hydrogen gas to the reservoir before, during, and after the replenishment process. This seamless operation guarantees that the system can produce hydrogen gas with a recovery rate and a deuterium D content ratio equal to or higher than the raw material water.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.