A recent patent filed by WISDRI Engineering & Research Incorporation Limited presents an innovative method to address challenges through the efficient use of waste heat from converter gas while also producing hydrogen.

This dual-purpose approach not only enhances energy utilization but also contributes to the growing demand for hydrogen, a clean fuel alternative.

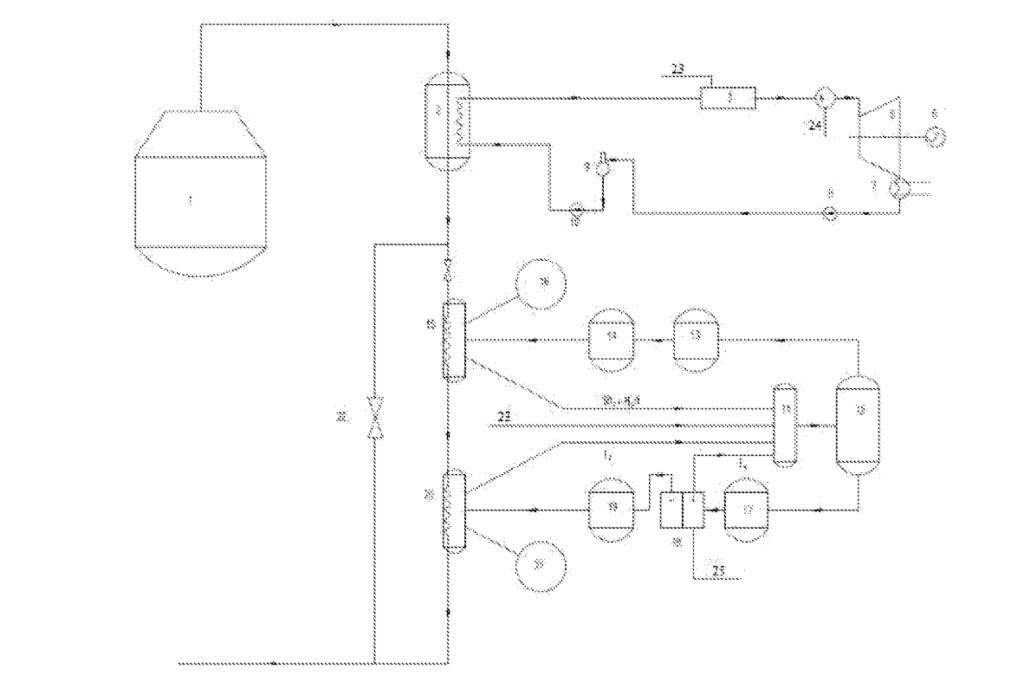

Converter gas, a byproduct of various industrial processes, often contains significant amounts of energy that traditionally go unused. The patented method begins with a meticulous converter gas procedure designed to capture and direct this energy toward more constructive purposes. By transforming previously wasted energy into a valuable resource, this method underpins the sustainability objectives that are becoming increasingly critical in industrial operations.

Following the initial capture of converter gas, the next stage involves waste heat recovery. Rather than allowing this thermal energy to dissipate into the environment, the method encompasses a recovery process that harnesses this heat for power generation. This not only helps in reducing reliance on traditional power sources but also cuts down on overall energy costs.

One of the most innovative aspects of this patent is its hydrogen production strategy. Using the sulfur-iodine thermochemical cycle, the method efficiently produces hydrogen gas. This cycle is an established chemical process that decomposes water into hydrogen and oxygen, utilizing the thermal energy collected from the converter gas. The outcome is a cleaner, more cost-effective production of hydrogen that aligns with the growing trend of hydrogen utilization in fields like metallurgy and sustainable energy solutions.

The implications of this patent extend beyond mere technical merit. By significantly reducing the costs associated with hydrogen production, particularly at the initial stages of hydrogen metallurgy, this method delivers considerable economic benefits. Concurrently, the full utilization of waste heat from converter gas represents a step forward in reducing industrial carbon footprints.