A striking 30% of hydrogen fuel samples from production plants typically fail to meet ISO 14687 purity standards for impurities like O2 and H2O. This statistic underscores the paramount importance of developing robust online monitoring systems to ensure the quality of hydrogen produced. In an era where clean energy sources are pivotal in transitioning towards a sustainable future, the precision and timeliness in monitoring hydrogen quality become critical.

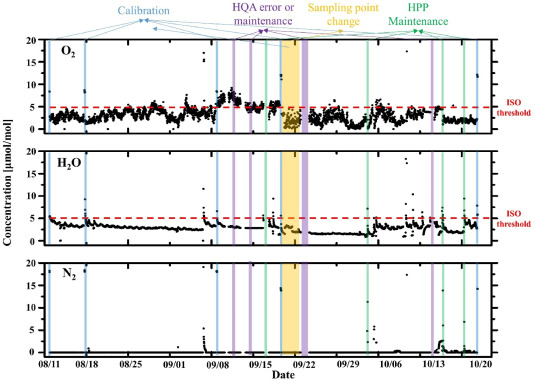

Integrating cutting-edge technology, a hydrogen quality analyzer (HQA) employing gas chromatography coupled with a pulsed discharge helium ionization detector (GC-PDHID) and a dew point transmitter (DPT) offers a promising solution. These technologies enable continuous online scrutiny of hydrogen purity, detecting impurities such as oxygen, nitrogen, moisture, carbon monoxide, carbon dioxide, and methane with notable efficiency. However, recent data from production plants reveal persistent violations of purity thresholds. Notably, oxygen and water vapor levels often surpass the ISO 14687 standards, suggesting potential inefficiencies or leakages in the hydrogen production process — a scenario that demands prompt attention and thorough investigation.

The core tension in hydrogen production revolves around ensuring stringent quality control amidst the rapid scaling of production facilities. Current market analyses show a projected annual growth rate of hydrogen consumption at 8% in the next decade. This growth trajectory heightens the stakes, necessitating technological advancements in quality assurance to prevent compromised fuel quality from entering the supply chain. The adoption of online monitoring technology could signal a paradigm shift toward more reliable hydrogen production, addressing the quality retention issues that traditional offline sampling methods present.

Unexpectedly, the online monitoring technology doesn’t capture all the impurities specified by the ISO 14687 standard, posing a challenge to its comprehensiveness. While GC-PDHID and DPT focus primarily on the most critical contaminants, the inability to detect a full range of impurities might initially appear as a limitation. However, by concentrating on these key indicators, it effectively mitigates prominent risks associated with hydrogen purity. Thus, a crucial insight emerges: while maintaining comprehensive detection remains ideal, prioritizing frequent impurities can create an actionable path that optimizes quality control without overwhelming system complexity or cost.

From a technical perspective, the implementation of online hydrogen quality analysis necessitates a recalibration of industry expectations and standards. Standards such as ISO 14687 should adapt to incorporate guidance on integrating these advanced monitoring technologies. This adaptation would empower producers to meet varying circumstances head-on, ensuring transparency and consistency in hydrogen purity levels.

Industry standards and best practices can no longer overlook the ramifications of subpar hydrogen fuel quality. The deployment of GC-PDHID and DPT within HQAs can significantly reduce relative standard uncertainty in identifying impurities — a critical parameter in the evaluation of certified reference materials. Moving forward, incorporating online technologies into Hydrogen Refueling Stations (HRS) and production facilities promises not only improved quality assurance but also enhances the overall efficiency of hydrogen distribution networks.

The advancement in hydrogen monitoring technology — demonstrated through online systems — indicates a future where real-time information feeds into a continuous improvement cycle for hydrogen production. The intersection of technology and industry standards presents an avenue for the hydrogen industry to address current efficiency woes and innovation bottlenecks, promoting a shift towards a more reliable and transparent ecosystem. As experts in the field, it is crucial to lend a critical eye to such innovations, ensuring they ultimately serve the broader goals of sustainability and efficiency without succumbing to superficial enhancements that merely scratch the surface of hydrogen production challenges.