Schlumberger Technology Corporation filed a patent titled “A Method of Oxy-Combustion” on July 18, 2024. The inventors or assignees, as listed, are responsible for advancing a method designed to enhance the efficiency and sustainability of combustion processes involving hydrogen and oxygen feedstocks.

Features and Improvements

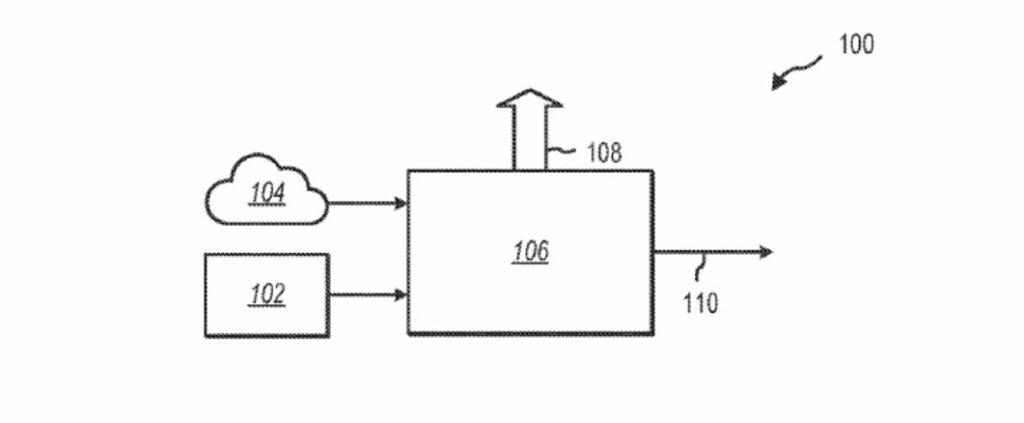

The patented method introduces a distinctive approach to oxy-combustion by utilizing an electrolyzer to split a feedstock into hydrogen and oxygen components. This process is integrated within a furnace where hydrogen and oxygen feedstocks are combusted. One of the patent’s unique aspects lies in controlling the second feedstock composition and pressure within the furnace alongside a recycling mechanism for exhaust steam. The steam recycling feature is particularly noteworthy, as it reintroduces exhaust portions into the system, making the process more efficient and less wasteful.

Applications

The applications of this patented technology are varied and significant. The primary use is in industries that involve high-temperature processes, such as steel manufacturing, glass production, and chemical processing. Using hydrogen as a combustion fuel can significantly reduce carbon emissions typically associated with fossil fuel combustion. Additionally, the recycling of exhaust steam can be applied in power generation plants to enhance overall efficiency and reduce operational costs.

Impact on the Hydrogen Market

This patent has the potential to impact the hydrogen market considerably. Optimizing the combustion process and incorporating steam recycling could lower the operational costs of hydrogen-based applications. This might encourage more industries to adopt hydrogen as a cleaner alternative to traditional fuels, thus accelerating the market shift towards more sustainable energy solutions. Furthermore, the integration of electrolyzers signifies potential synergies with renewable energy sources, promoting the use of green hydrogen.

Comparison with Existing Solutions

This patented method offers enhanced efficiency and reduced waste compared to existing technologies. Traditional combustion processes often suffer from energy losses and do not typically incorporate mechanisms for feedstock recycling. By addressing these inefficiencies, Schlumberger’s method presents a more sustainable and cost-effective solution, aligning with current trends in industrial decarbonization and energy efficiency improvements.

Technical Specifications and Processes

Key technical specifications of the patent include:

– An electrolyzer cell for splitting feedstock into hydrogen and oxygen.

– A controlled combustion process within a furnace addresses feedstock composition and pressure.

– A recycling system for exhaust steam reintroduces portions of it back into the feedstock, optimizing resource use and reducing emissions.

Key Takeaways

Schlumberger Technology Corporation’s patent for oxy-combustion introduces a forward-thinking approach to industrial fuel use. Integrating electrolyzers for hydrogen and oxygen separation and a robust recycling mechanism for exhaust steam drives efficiency and sustainability. Potential applications span various high-temperature industrial processes, promising reduced operational costs and carbon footprint. This method stands out by offering improvements over current combustion technologies, aligning well with the ongoing shift towards greener industrial solutions.