Schaeffler Technologies AG & Co. KG has filed a patent for an advanced electrode plate explicitly designed for electrolysis systems used in hydrogen production. The invention features a meticulously designed electrode plate made of sheet metal to enhance the efficiency and durability of hydrogen production processes.

Features and Improvements

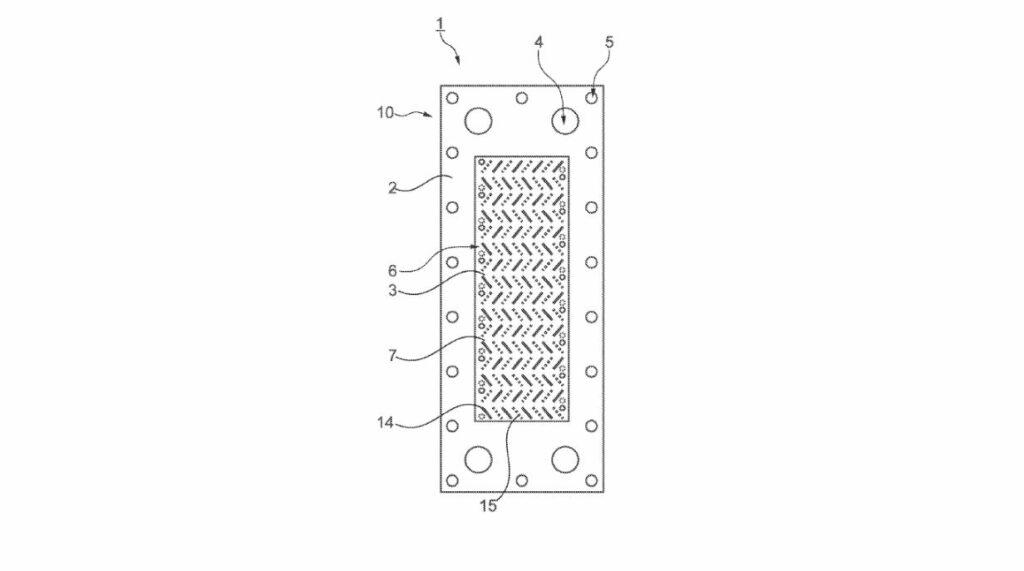

The patented electrode plate stands out due to its active field featuring an embossed structure. The arrangement consists of raised and recessed linear embossed strips in a meticulous row and column pattern. This geometric arrangement creates an alternating raised and recessed pattern, optimizing the flow direction parallel to the longitudinal side of the active field.

One of the key innovations is the inclination of the embossed strips. Each row’s strips are inclined identically, while the following row’s strips have equal but opposite inclinations. This design increases the efficiency of gas bubble release and liquid flow, substantially improving the electrolytic performance compared to flat or randomly embossed surfaces.

Applications

The innovative electrode plate is primarily intended for use in electrolysis systems for hydrogen production. Given its enhanced efficiency, it has the potential to be utilized in various sectors, including:

– Industrial hydrogen production plants

– Renewable energy storage solutions

– Fuel cell technology development

– Hydrogen refueling stations

The introduction of this advanced electrode plate could have several implications for the hydrogen market:

1. Increased Efficiency: Improving the electrolytic efficiency can make hydrogen production more cost-effective, potentially reducing the overall price of hydrogen.

2. Broader Adoption: Greater efficiency and reduced costs could facilitate the broader adoption of hydrogen as an alternative energy source.

3. Technological Advancement: This patent represents a step forward in electrolyzer technology, promoting further innovations and improvements across the industry.

When compared to existing solutions, Schaeffler Technologies’ electrode plate offers distinct advantages:

– Efficiency: The unique embossed structure promotes better gas release and liquid flow, outperforming flat electrode surfaces.

– Durability: Using sheet metal and well-designed embossed patterns enhances the longevity of the electrode plate.

– Scalability: The embossed design’s straightforward manufacturing process ensures that it can be produced at scale without significant cost increases.

Technical Specifications

The key technical aspects of the patented electrode plate include:

– Material: Made of sheet metal, providing robustness and durability.

– Design: This design features an active field with a rectangular frame, hosting a series of linear embossed strips in a row-and-column arrangement.

– Embossing: Alternating raised and recessed linear strips, inclined identically within each row and oppositely between consecutive rows.

– Flow Optimization: Designed to promote efficient flow direction and gas bubble release.

Schaeffler Technologies AG & Co. KG’s new patent for an electrode plate for electrolysis systems introduces an innovation that enhances the efficiency and durability of hydrogen production. The unique design improvements are likely to positively impact the hydrogen market by reducing production costs and promoting wider adoption of hydrogen as a clean energy source. Compared to existing technologies, this electrode plate offers clear advantages in performance and scalability, positioning Schaeffler Technologies as a key player in advancing hydrogen production technology.